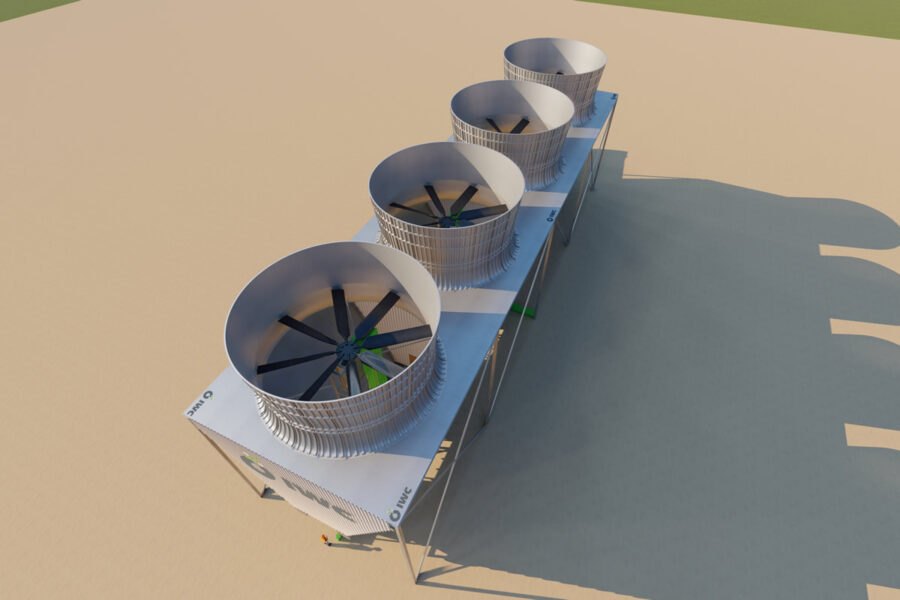

IWC launches new range of Air Cooled Condensers

As a global thermal solutions specialist we are no strangers to developing innovative designs and products. Our new range of Air Cooled Condensers will certainly set the benchmark for ACC’s going forward.

The development project is headed up by Dr Hanno Reuter, who heads up the IWC Consulting Division. Hanno is internationally experienced in thermo-fluids, performance modelling, design, engineering, testing, R&D and management in the field of industrial wet, dry and combined dry/wet cooling systems and thermal power plants.

After months of detailing and designing, we are ready to go to market with the new range. We have also enlisted the assistance of Stellenbosch University who will be conducting tests on the finned tubes that will be used in our ACC’s. Our range includes the induced draft air cooled condenser as well as the forced draft air cooled condenser.

With climate action at the heart of the IWC growth strategy, our aim is to produce an Air Cooled Condenser that is designed to have a lower environmental impact by targeting a reduction in water use, energy use and carbon emissions.

Unlike traditional cooling towers that evaporate water to remove heat from a system, ACC’s use air as the cooling medium. This reduces the water usage of the system and can be particularly beneficial in water-scarce areas.

The one drawback of using an ACC is that power plant efficiencies are significantly lower than with traditional cooling towers, resulting in higher CO2 emissions per unit plant output. However, this can be mitigated by incorporating an IWC Hybrid (Dry/Wet) Dephlegmator (HDWD).

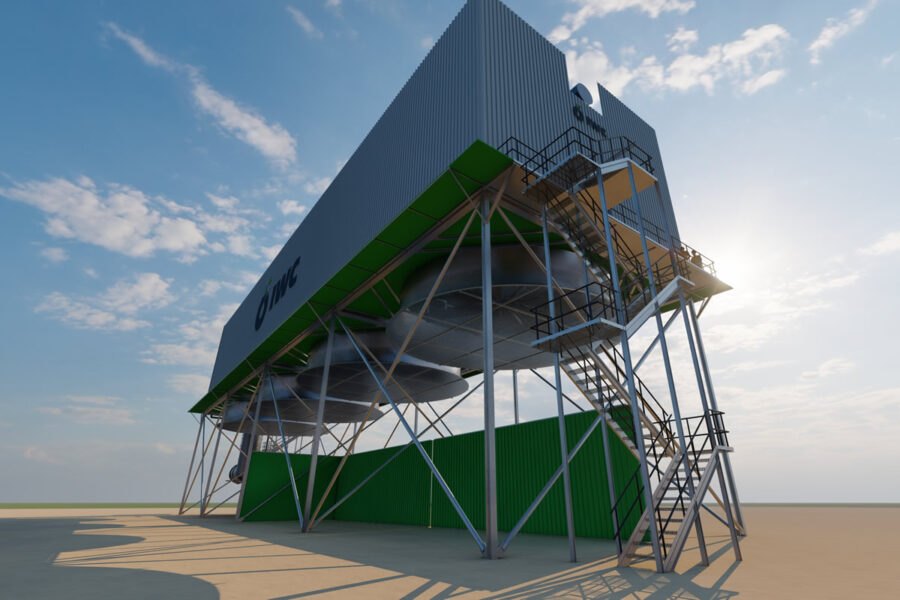

When employing an induced draft ACC, less structural steel is needed for construction and erection is simpler than for a forced draft ACC, which means less CO2 is emitted from steel manufacturing and the erection process.

Why choose our ACC?

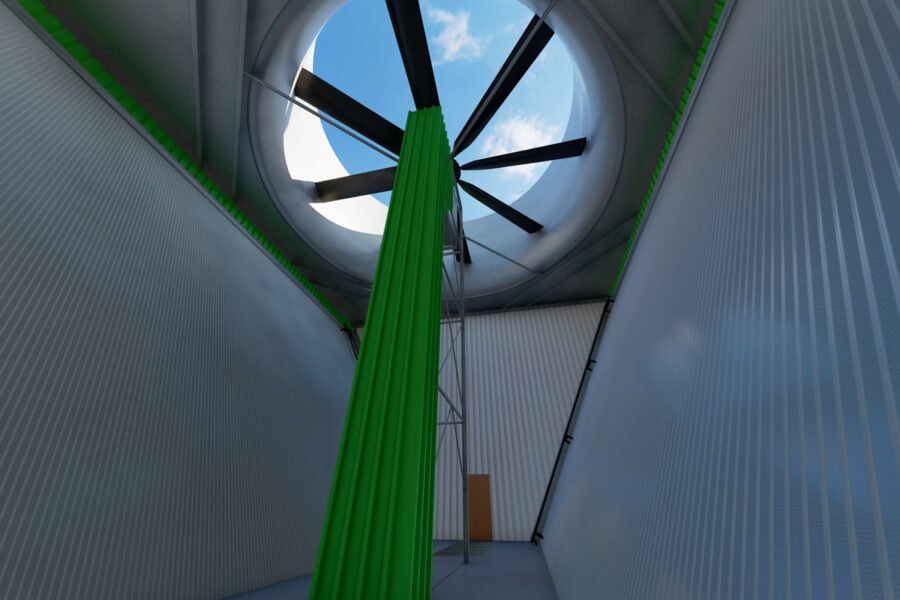

- Simplified removal of motor and gearbox assembly for repair/ maintenance.

- Ambient air-cooled motor and gearbox.

- Ventilated access ladder and platform for gearbox and motor maintenance.

- Simplified erection as steam duct is below the bundles, mechanicals are on a separate central structure and less components.

- Reduced plot size due to diffusers on the fan stacks.

- Simple conversion to dry/wet configuration using hybrid (dry/wet) dephlegmator technology on the same plot size as ACC only cooling.

- Parallel shaft gearboxes are used with higher efficiencies than right-angled gearboxes.

- Single tube cleaning system required per side due to hatches in the plenum walls.

Want to find our more?

Visit our stand D43 at the Enlit Africa exhibition in Cape Town. The exhibition will be held at the CTICC from 16 -18 May.

Or read more about our existing range.