Cooling Towers

Components / Spares

We offer a comprehensive range of spares and accessories for all cooling tower types, including fills, motors, drives and nozzles.

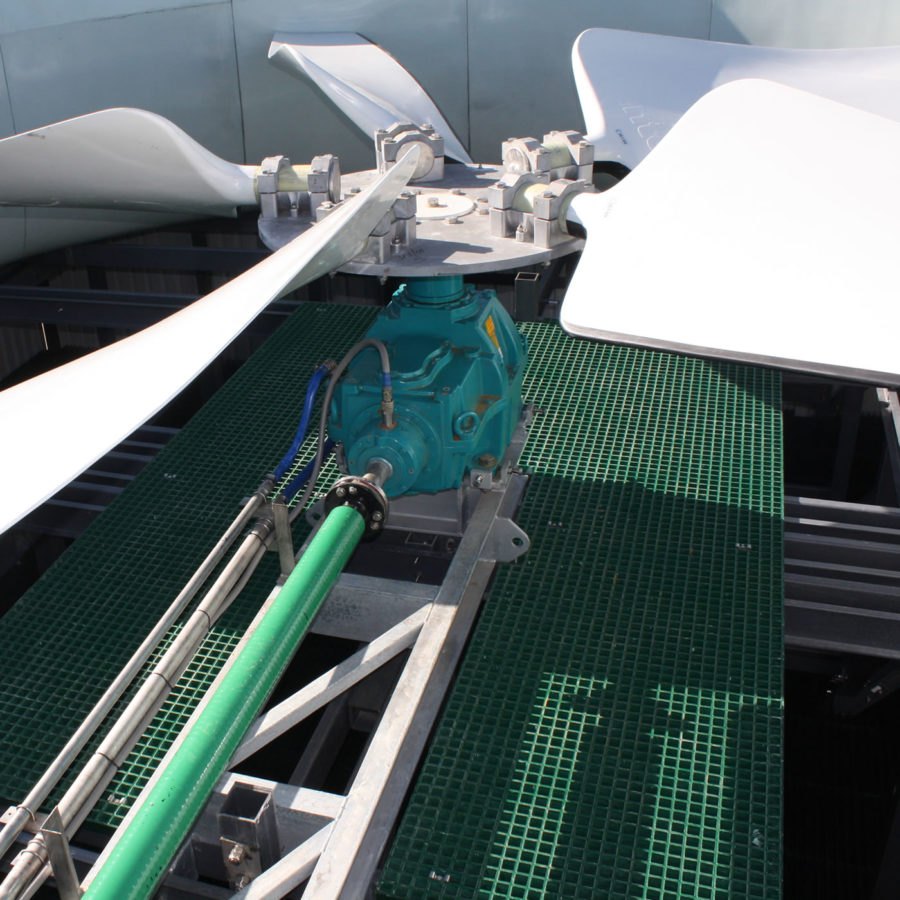

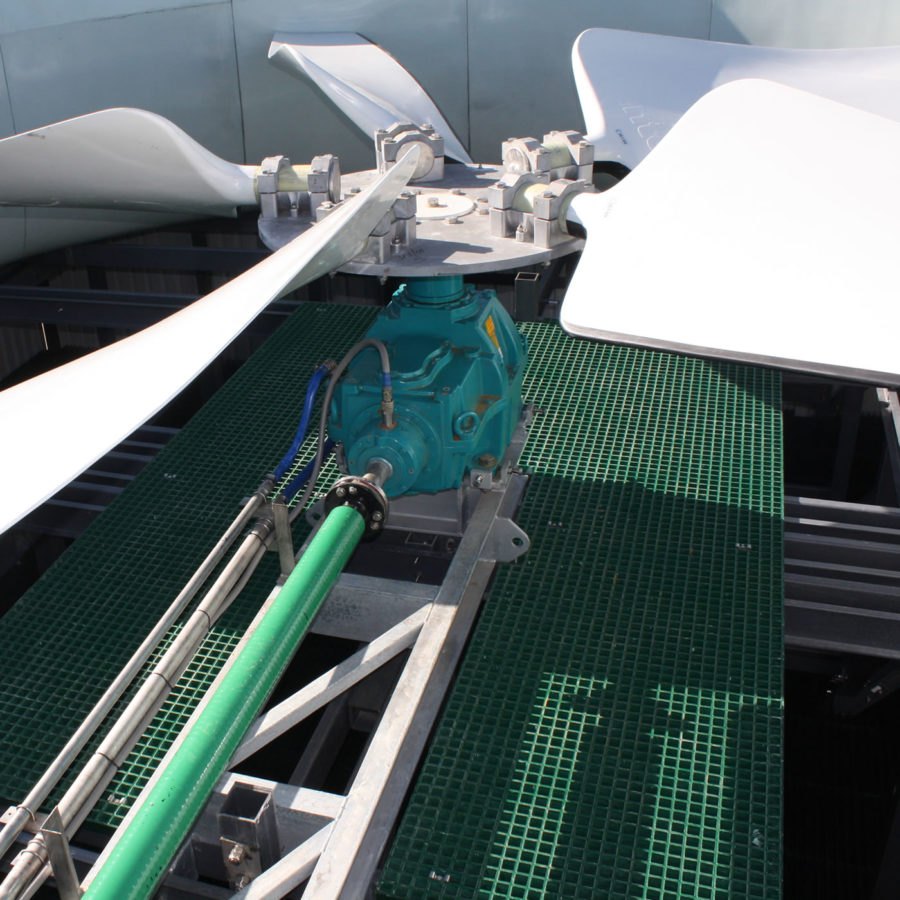

Fan Rotating Assembly

IWC supplies a range of fans and fan equipment to retrofit almost any cooling tower or air-cooled heat exchanger.

Our standard fan arrangement comprises an axial flow fan having either fiberglass or aluminium fan blades, right angle reduction gearboxes, steel, stainless steel or carbon fibre composite drive shafts and electrical motors supplied to our customers specifications.

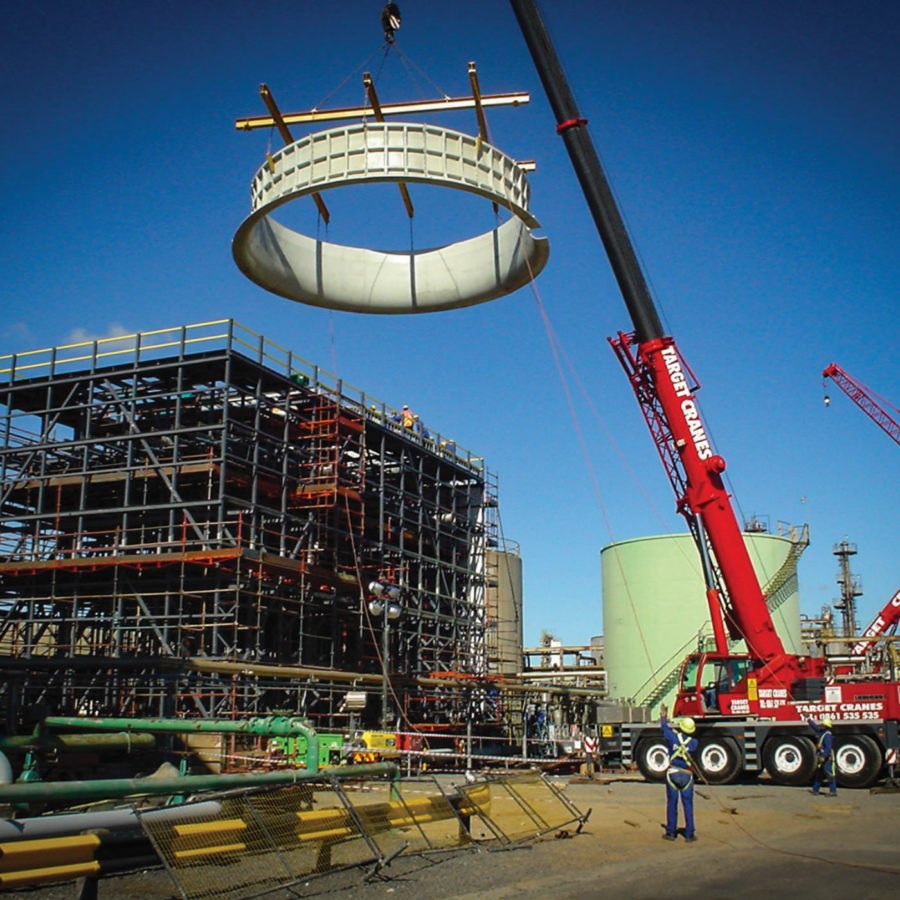

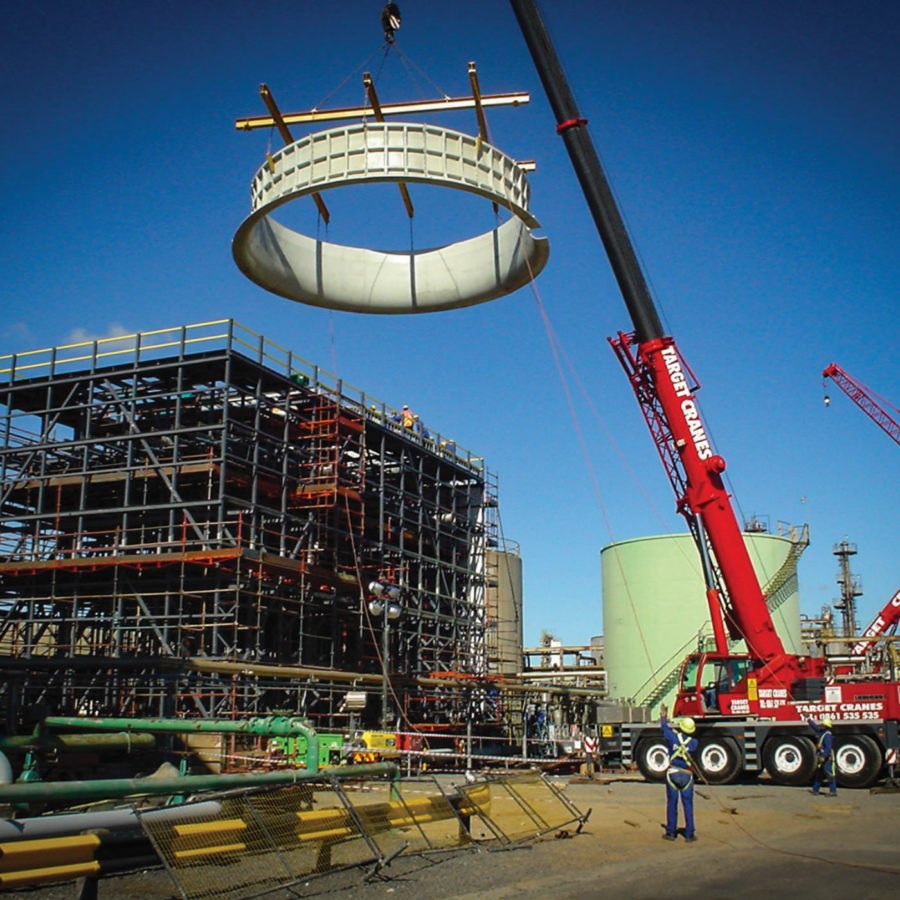

Fan Rings or Fan Stacks

We provide fibreglass fan rings and fan stacks for both air-cooled heat exchangers as well as cooling towers.

These are supplied complete with bell, circular or conical inlets. Pressure recovery diffusers/evasés are available as optional equipment.

Cooling Tower Fills

We have a comprehensive range of cooling tower fills on offer. Our range of media covers all possible cooling tower operating conditions from very clean to extremely dirty recirculating water.

Our fills are typically available in either PVC or polypropylene, with the exception of our splash grid fill that is only available in polypropylene. We also provide different types of trickle fill packs including our IWC20T. We also offer timber or stainless steel fill options.

Drift Eliminators

A variety of drift eliminators are available depending on the customers emission requirements. These typically include our S-Type (large cooling towers) & Honeycomb D15 (typical in package cooling towers).

Drift eliminators can be provided in a range of materials with PVC and polypropylene being the industry standard. Stainless steel can be provided for high temperature and high fouling applications. EUROVENT certified products can be provided on request.

Water Distribution Systems

The distribution system is at the heart of a cooling tower’s performance, so replacing a sprayer with one that wasn’t selected or designed to meet a cooling tower’s specific flow rate and distribution pattern, will impact the overall cooling tower performance.

IWC is the only South African cooling tower company that manufactures its own range of cooling tower sprayers. Our aim to provide OEM equipment is driven by a need to provide outstanding, long lasting components that will enhance the performance of your cooling tower.

Square Pattern Sprayers

Our sprayers have been designed with profiled swirlers to ensure uniform water distribution at a low static pressures.

All our sprayers develop a full cone square pattern with a minimum spray angle of 110°. This means that a single sprayer can be used to cover an area of 1 square meter with the sprayer tip positioned 350mm above the cooling tower fill, or 1.2 square meters with the sprayer tip 380mm above the fill. We also stock pipe saddles to suit the above sprayer and these are available to suit 110mm, 160mm and 200mm pipe diameters.

They cover flow rates of 8 – 35m³/hr between pressures of 1.5 – 6 metres of head. The sprayers can be fitted into standard 3” BSP metal or plastic fittings or used with the IWC saddles. We are also able to offer new distribution piping systems for any cooling tower made from PVC, polypropylene, various grades of stainless steel and other materials. Our sprayers are also available in ABS plastic and are suitable for operation up to 70°C.

Up & Down spray nozzles

Our up and down spray nozzles are low pressure gravity fed sprayers designed to achieve excellent water distribution at low water pressures making them ideal for large field erected mechanical and natural draught cooling towers.

The graduated spray nozzle makes nozzle sizing simple. These can be fitted to standard 2”BSP metal or plastic fittings but are ideally used with IWC”s saddles that are available for a range of pipe diameters.