A real live Meccano build, right in the middle of Africa

According to Bloomberg, Tanzania plans to more than double sugar output in the next three years. Currently, the country produces about 320,000 tonnes of sugar and with more land being set aside for growing cane and more mills starting production, Tanzania is set to become a net exporter of sugar by 2022.

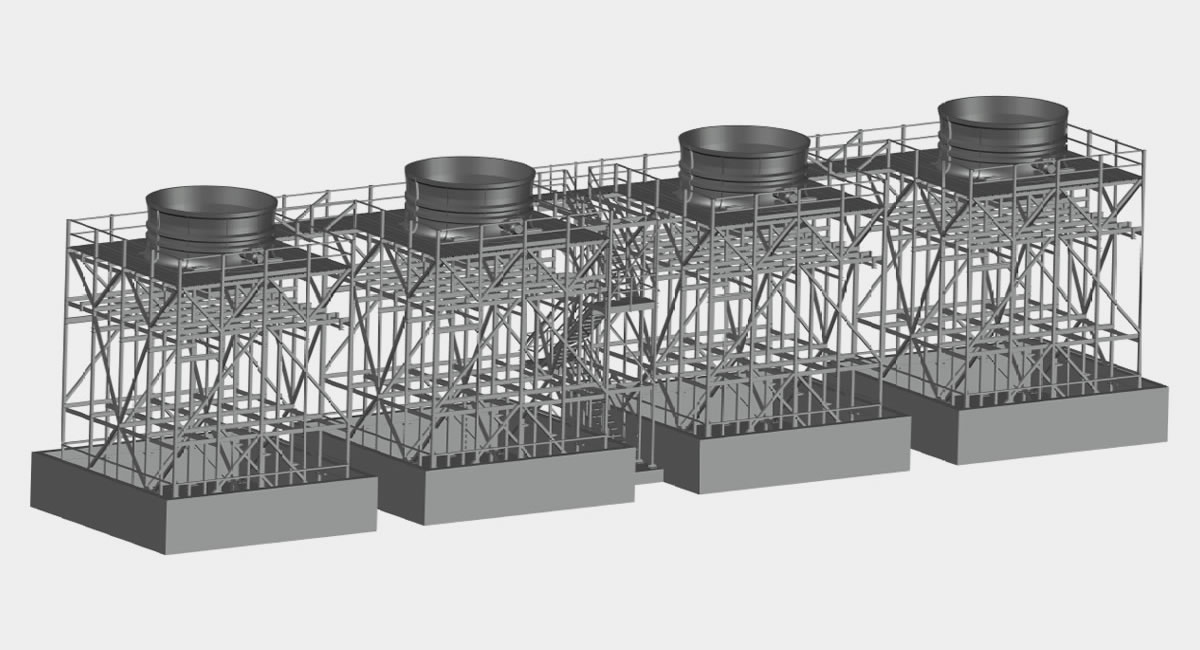

In pursuit of this goal, Kagera Sugar Company enlisted the help of IWC in 2018 for the design, supply and construction of a 4-cell counter flow, pultruded glass reinforced plastic cooling tower. Glass-reinforced plastic (GRP), is a composite material made of a plastic reinforced by fine fibres made of glass. It’s a modern material that has many advantages over traditional construction materials like concrete, steel or wood.

With the Kagera Sugar Company factory situated in a remote area, all the materials required for this project had to be containerised and transported by ship from South Africa to Tanzania and then road freighted to site. A real live Meccano build, right in the middle of Africa. Industrial Water Cooling provided the necessary site manager for the erection of the cooling tower – using local labour – and completed the work in five weeks.

On the back of the successful 2018 project, IWC were recently awarded another contract to supply four new individual cooling tower cells. The new project is in full swing with all the cooling tower components already delivered to Tanzania, ready for erection. Cooling tower erection will be done by Kagera Sugar under supervision by our skilled engineers. Construction is expected to commence in October and we look forward to the completion of this project.

Why IWC?

IWC have been providing innovative and effective cooling solutions for over 30 years throughout Africa. Our extensive sugar industry experience and vast range of products enables us to provide cutting edge cooling solutions to an industry which makes up a crucial part of Africa’s future.