Phase 1

Phase 2

It’s no wonder then that the mine operations at the 11 working mines in the area need super bulk air cooling to ensure mine efficiency and safe working conditions for miners.

Who better to assist with this than IWC, a global thermals solutions provider who design, build and assemble cooling towers for mines.

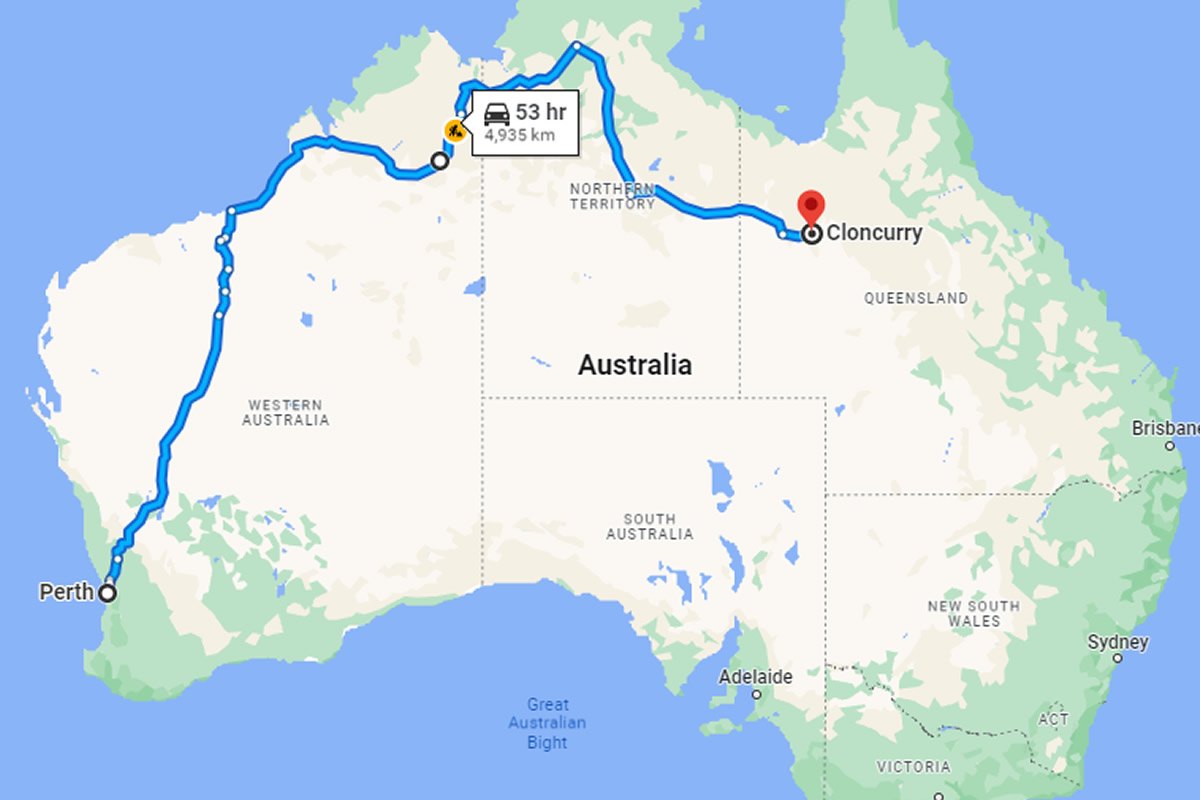

IWC were contracted by Gordon Brothers to supply the cooling towers used in the refrigeration plant for the underground mine cooling at the Ernest Henry Mine. The mine is now owned by Evolution who bought the mine from Glencore. The Ernest Henry copper-gold operation employs sub-level caving or extraction and it is located 38km north-east of Cloncurry, Queensland on the traditional lands of the Mitakoodi people.

IWC supplied the original 2 condenser cooling towers for phase 1 while still owned by Glencore and the latest cooling tower supplied is for the second phase.

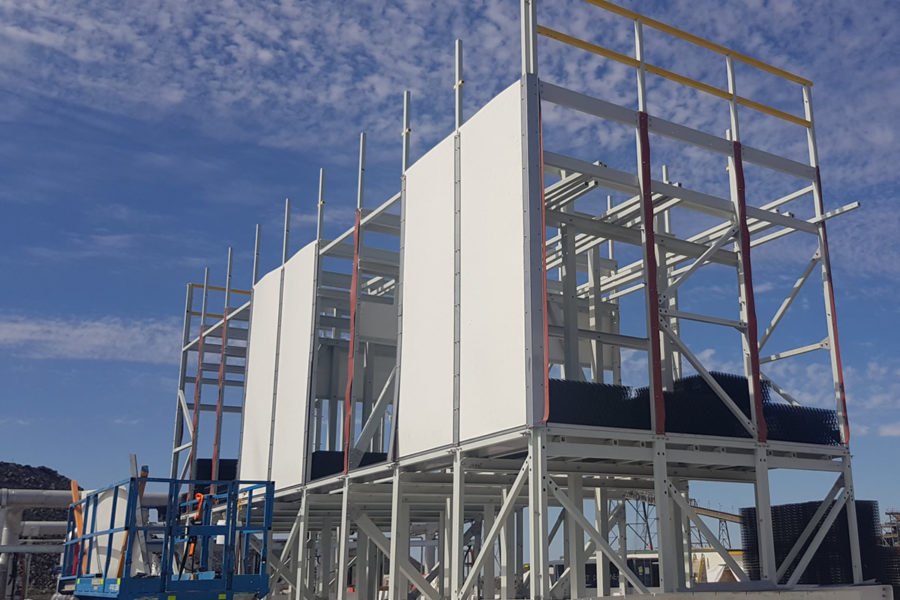

Our PLT Cooling Tower is a range of custom built towers for use in medium to large size applications and is made up of a glass reinforced polyester (Pultruded fiberglass) frame, side sheets and glass reinforced polyester fan casings.

The tower was designed by IWC South Africa and then assembled at IWC Australasia’s facility in Perth (Western Australia) . The cooling tower was then transported to site by truck to the Ernest Henry Mine, a journey of almost 5 000kms.

The end result is a very happy client, even though some issues were encountered on the stage 1 project. Well done to IWC Australasia for another successful project.