Industrial Water Cooling and winemaking… a partnership best served chilled

The art of winemaking goes back many centuries, and over the years, technology has improved enabling greater experimentation and refinement in the winemaking process. However, a well-maintained cooling system remains at the core of producing a great tasting final product. Whether looking to break into the wine industry or seeking to update existing wine production systems, understanding the role of cooling in the process is essential.

Where is cooling used when making wine?

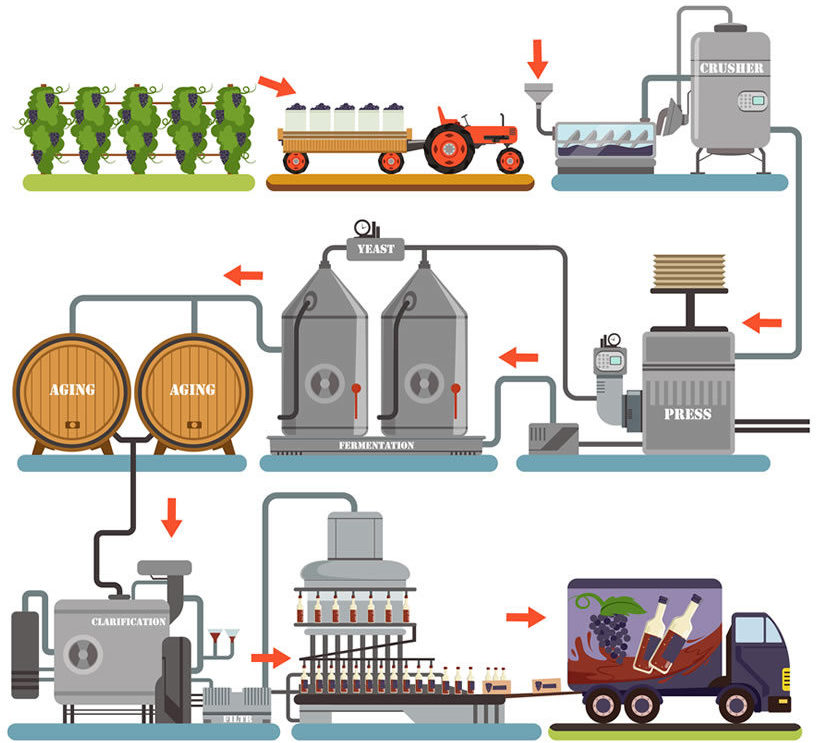

Temperature control impacts several steps within the winemaking process. The first step in the process is creating the must. The must is created by the grapes dropping through the crushing rollers, which are set to burst the skins, but n ot to crush the pulp or pips.

The must, a wet mixture of grape skins, seeds and stems is cooled and the first dosing of SO2 is added. The must is pumped through a mash-cooler, a system of refrigerated jacketed pipes which form a heat exchanger, or the must is pumped into a closed refrigerated tank. The length and temperature at which the must stays in this stage influences the final flavours of the wine.

Fermentation is the second step in the winemaking process that requires cooling. This step is generally the longest in the process and it involves the careful management of added yeast, which break down the sugars present in the juice. As the yeast consumes the sugar, the liquid ferments and receives its alcoholic content. Many factors contribute to the rate of fermentation and the final flavour, but temperature remains the key determinant. Temperature must be properly set and regulated to produce flavourful wine. The fermentation process could stop if temperatures become too high..

The IWC produced range of EWK package cooling towers are an integral part of the refrigeration equipment that supplies cold/chilled water to both the mash-cooler as well as the fermentation process.

What is a cooling tower and why is it used?

In simple terms, a cooling tower is a device designed to reject unwanted heat into the atmosphere. Water is a highly effective heat transfer medium and as such is used extensively in the wine industry for rejecting heat generated in the refrigeration process.

Why choose our towers?

Our iconic EWK cooling tower range is well suited for use in the wine industry and we have a large installation footprint across the Western Cape. Our towers are manufactured in a robust, durable and compact glass reinforced polyester casing. Our cooling towers are 100% South African made and we stock a large range of spares to assist customers at short notice.

Further advantages

- Non-corrosive and light weight

- Reliable

- Low energy consumption and easy to maintain

- Plug and play design results in a simple installation