IWC’s Innovative Cool Solution for Tight Spaces

In a world of industrial challenges, where budgets are tight and space is limited, a remarkable solution emerged. Isizwe Components needed an efficient cooling solution, and IWC had just the answer. Let’s dive into the story of innovation in tight spaces.

Requirement

Our client, Isizwe Components required 11 000 kW’s of cooling with limited space and on a strict budget. IWCs’ robust FGS range of cooling towers were the perfect solution for this requirement and as space was a challenge, the positioning of the cooling towers needed careful consideration too.

Solution

Isizwe Components’ recently installed new dyno makes it the largest privately owned dyno in South Africa. Servicing and overhauling the mining industry’s earth moving machinery is no easy task, the engines are large and bulky and you need space to manoeuvre. Access to space is essential in ensuring Isizwe Components’ operations run smoothly.

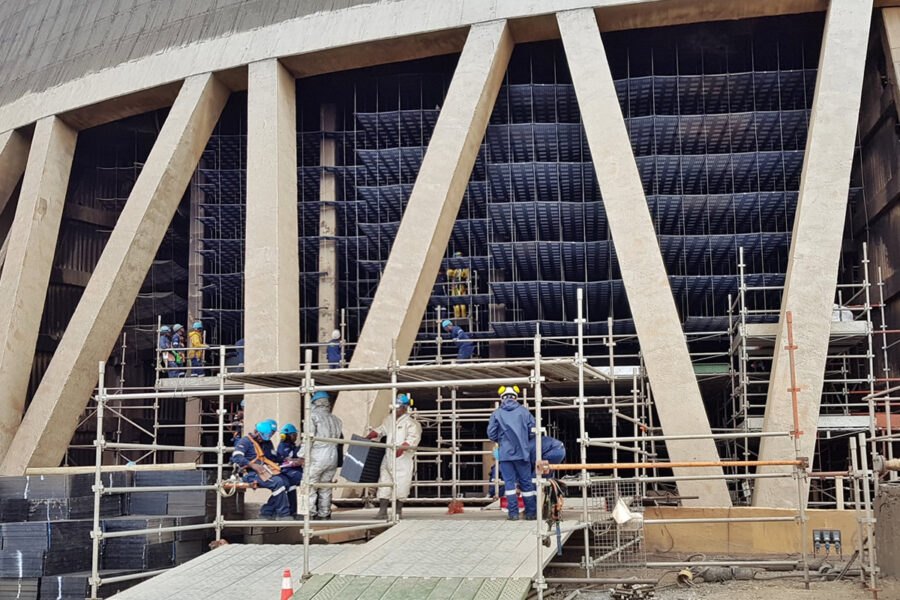

With this in mind, the IWCs’ team of resident engineers designed a custom engineered, 6m high platform to fit within the limited space available, whilst still providing Isizwe Components’ access to three roller doors in the vicinity.

Based on the height of the access doors and the factory roof, our design not only ensured access to the roller doors was free from obstruction, but also ensured that the warm discharge air was released above the roof line. This practice is critical to ensure that the warm discharge air is not recirculated though the cooling towers, which results in reduced efficiency.

We also supplied and installed four FGS65 cooling towers, with three circulation pumps and NB250 inlet and outlet manifolds. The 6m high cooling tower platform was supplied with an access ladder and grated walkway to ensure maintenance on the cooling towers would be a breeze.

Our new cooling system provides cooling to the dyno, as well as two heat exchangers and two charge air cooling applications.

Our innovative solution to Isizwe Components’ challenging cooling requirements exemplifies the company’s commitment to engineering excellence and customer-centric problem solving by designing and implementing a bespoke-engineered elevated platform solution. The installation of four FGS65 cooling towers, circulation pumps and the necessary manifolds further showcased IWC’s technical prowess.

This project not only met the client’s stringent cooling demands but also contributed to the seamless operation of Isizwe Components’ mining equipment servicing, making it a pivotal asset in South Africa’s mining industry.

IWC’s dedication to providing cutting-edge cooling solutions within budget constraints demonstrates its position as a reliable partner in industrial cooling, offering not only efficient temperature control but also the peace of mind that comes with top-notch engineering. Furthermore, our industry leading 10 year guarantee on FRP (Fibreglass) components ensures peace of mind. As the largest privately-owned dyno in South Africa now benefits from IWC’s expertise, it’s evident that the company’s commitment to excellence continues to drive success in the industry.