Cooling Tower Refurbishment under way at Kriel

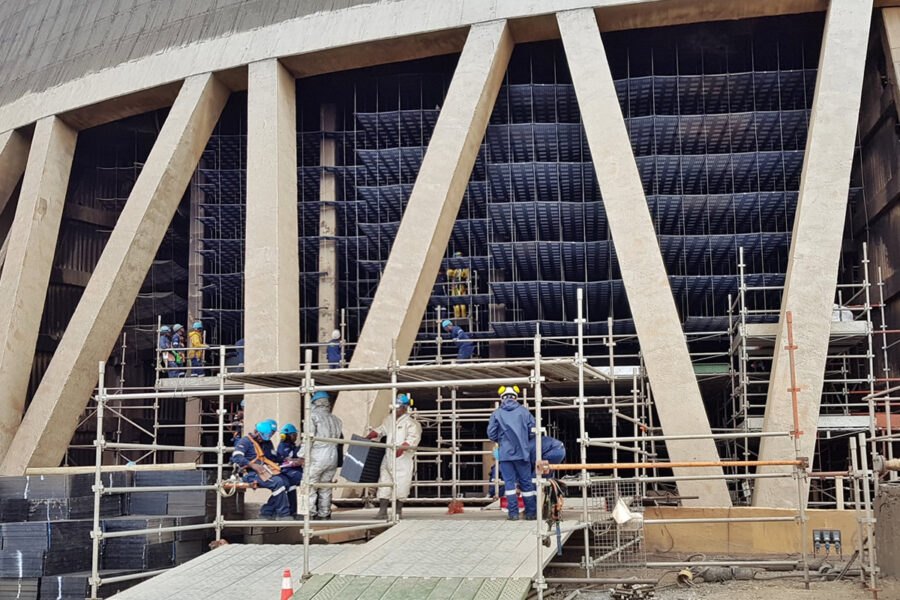

Thermal solutions specialist Industrial Water Cooling (IWC) is working with State-owned power utility Eskom on the refurbishment of two natural draught cooling towers at its Kriel power station, in Mpumalanga.

The refurbishment includes the installation of fiberglass-reinforced plastic (FRP) supports and polypropylene trickle fill, high-pressure cleaning of the ducts and distribution pipes, as well as the replacement of drift eliminators, sprayers, and ladders.

IWC will also be tasked with replacing the obsolete cooling tower internals, and potentially unsafe and/or deteriorated asbestos material.

Once the cooling towers have been brought back online, they will operate at a much-improved capacity, as the water will be cooled to the required temperatures, which will, consequently improve efficiencies and enable the plant to generate more megawatts.

“IWC started work on this project in June – with trickle-fill assembly on site – so that installation activities could start as soon as the outage starts,” says IWC project director Gordon Beckett.

The outage has been scheduled over a three-month period, with the commissioning of the last cooling tower expected towards the end of October.

The initial project brief was to complete one cooling tower during this period; however, IWC has undertaken the commissioning of the second cooling tower during the same time, which will require “unprecedented project management skills and teamwork”, adds Beckett.

“Our scope of work is based on Eskom technical specifications, as well as compliance Eskom procedures and industry standards.”

He adds that IWC is ISO 9001 compliant, which, in turn, allows for the company’s work to be managed and executed in line with industrial requirements.

Beckett says although IWC does not foresee any major challenges on the refurbishment, “…the limited time will keep our dedicated team on their feet, as they’ll need to tackle anything that comes their way in an expeditious manner”.

Any challenges will be mitigated and managed by the experienced project management team; IWC’s safety, health, environment and quality manager and its skilled supervisory staff.

“As part of the contractual obligation to the project, we offer post-project maintenance and service contracts,” he adds.

IWC’s parts and workmanship are guaranteed for any defects that may be identified during the specified periods, in addition to a full maintenance programme for future maintenance activities.

Not the First or the Last

IWC completed the refurbishment of three other natural draft cooling towers in May at the Eskom-owned Matla Power Station complex, in Mpumalanga.

The refurbishment scope included the removal of 28 700 t of asbestos cement materials from the cooling towers, as well as the installation of FRP fill supports, new polypropene trickle fill, polyvinyl chloride drift eliminators, and cleaning works.

“The entire project was completed within two months, ahead of schedule with no injuries – all in all, a very successful project,” lauds Beckett.

The cooling towers are now operating – as planned – at improved efficiencies similarly to what is projected for the Kriel project.

“Another huge win for us was that we were able to help the surrounding community by upgrading the local Lehlaka Combined School, which was in dire need of a refurbishment,” he adds.

As part of the corporate social investment requirement by Eskom to all suppliers, IWC was tasked to use the local workforce for the school refurbishment project to help uplift the broader local community.

“What better way than to support the future adults of the area through the school’s upliftment project,” says Beckett.

The bathrooms were fitted with new basins, toilets and taps; security bars and doors were installed at the premises; and the wiring in the classrooms was repaired, with the classrooms now having working lighting. We also painted the entire school, inside and outside which has transformed the school completely.

IWC provided backpacks, which included school supplies and water bottles, to all the children, which were “very well received”.

“We believe that IWC is one of Africa’s leading cooling tower refurbishment specialists, with high levels of safety and quality, and we believe we are in the running to complete further large refurbishment projects for Eskom,” he concludes.