Requirement

A cooling solution to facilitate the milling production of sugar in the remote area of Tanzania.

Solution

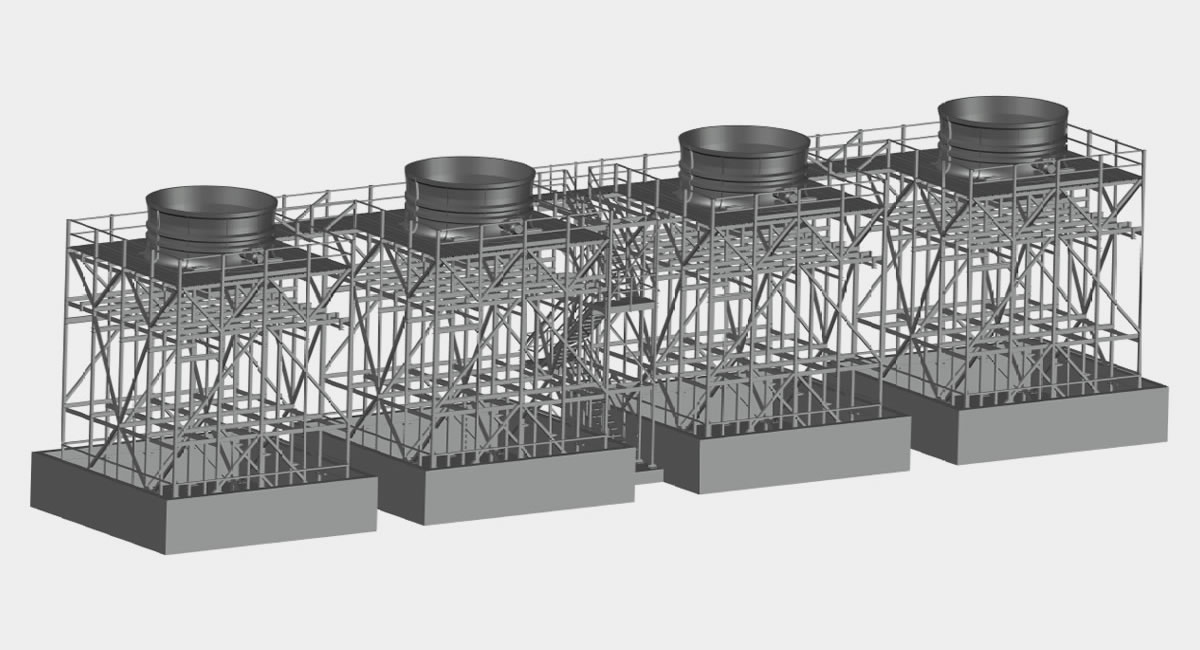

We designed and supplied a 4-cell counter flow, pultruded glass reinforced plastic cooling tower. Glass-reinforced plastic (GRP), is a composite material made of a plastic reinforced by fine fibres made of glass.

As the Kagera Sugar Company factory is situated in a remote area, all the materials required for this project had to be containerised and transported by ship from South Africa to Tanzania and then road freighted to site. A real live Meccano build, right in the middle of Africa. IWC provided the necessary site manager for the erection of the cooling tower – using local labour – and completed the work in five weeks.

SHARE

Products used in this project