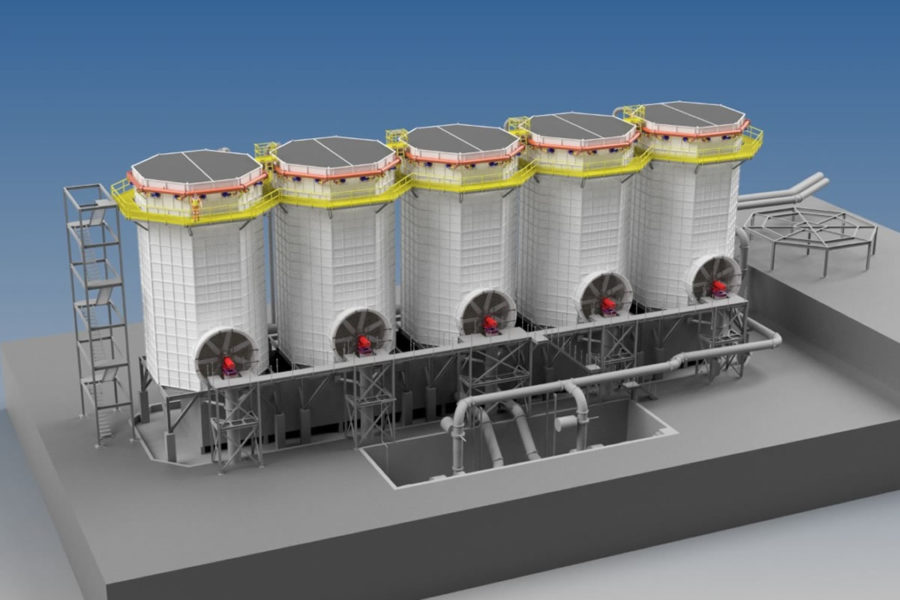

Slurry cooling towers, the perfect solution for gold and copper mines

Specifically designed and developed to handle slurries and zinc solutions, as well as highly abrasive and/or corrosive solutions; our forced-draft counterflow cooling towers are ideal for cooling slurry with high levels of suspended solids, extreme temperatures and highly aggressive chemical compositions.

Typically octagonal in shape, the tower comprises of several field-assembled, dual-composite glass-reinforced plastic panels, constructed for safe and sustainable performance.

Structural panels have integral polypropylene liners and a laminate produced from a high quality vinyl ester resin. The conductive carbon tissue is included as a corrosion barrier to allow for spark testing of the internal polypropylene panel seal welds and can accommodate solution temperatures of up to 80°. We are also able to construct the slurry cooling towers from special duplex stainless steel.

As the towers have no fill, the possibility of fouling and corrosion within the cooling tower is limited.

Another advantage of IWC’s slurry cooling towers is that drift eliminators are assembled into easily removable pads allowing for safe cleaning at ground level. An automatic CIP (cleaning-in-place) system can also be included. Drift losses can be reduced to as low as 0,0002% of the recirculating solution flow rate.

The robust design, easy assembly, low maintenance costs and guaranteed operational efficiency, ensure extended service time of operational machinery.

Why IWC?

IWC have been providing innovative and effective cooling solutions throughout Africa for the last 30 years. Our successful installation footprint of 5 slurry cooling towers at the Kansanshi Copper Mine in Solwezi, northern Zambia is testament of this.

We are also currently busy with the fabrication phase for 8 slurry cooling towers for a gold mine in the Caribbean.