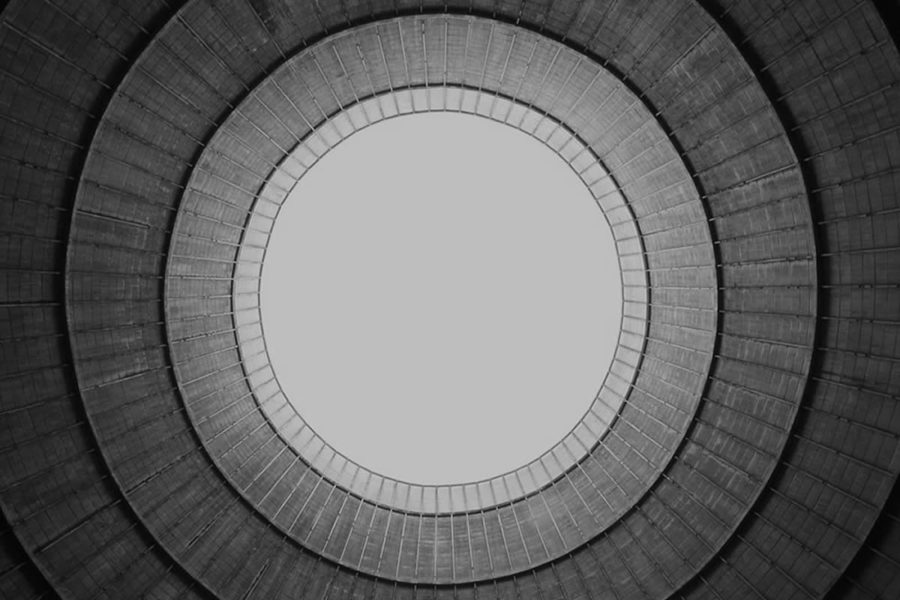

Top Cooling Tower Filtration Systems Reduce Water Consumption and Maintenance

Cleaner, more efficient cooling towers can be easily maintained by installing the right filtration system. Keeping process-water clean is essential to maximising the efficiency and performance of an industrial cooling tower system. Dirty process water corrodes cooling tower equipment, reducing heat exchange efficiency, driving up energy costs, leading to unnecessary water wastage. In addition, unclean water can lead to the growth of microbes such as the deadly Legionella bacteria.

Evaporative cooling towers dissipate unwanted heat through water evaporation. When water evaporates from the tower, dissolved solids (such as calcium, magnesium, chloride and silica) are left behind. As more water evaporates, the concentration of dissolved solids increases. If the concentration reaches a level higher than the saturation point of the cooling tower, the solids cause scale to form within the system, which eventually corrodes the process equipment, leading to reduced system efficiency and the need to replace system parts more frequently. A high concentration of solids can also lead to the growth of microbes, including the Legionella bacteria, which causes Legionnaires’ disease.

To reduce the build-up of suspended solids, the cooling tower’s process water is flushed out (blowdown) and replaced with fresh water, known as make-up water. In addition to controlled blowdown, the water is sometimes chemically treated to reduce biological growth. Used alone, these methods can lead to high water wastage and pollution as the treatment chemicals are released into the environment through the evaporative process. A more effective method to clean a cooling tower’s process water is by installing cooling tower water filtration systems, which dramatically reduce suspended solid build-up and cut down on the need for process water to be chemically treated.

Blowdown is quantified by cycles of concentration, which is the ratio of the concentration of dissolved solids in the blowdown water compared to the make-up water. It is also approximately equal to the ratio of volume of make-up to blowdown water. Using an efficient filtration system combined with filtration technologies such as screen filters and centrifugal separators means cooling tower operators can maximise cycles of concentration, which in turn reduces cooling tower make-up water by 20% and cooling tower blowdown by 50%

says Mr Roger Rusch, CEO of Industrial Water Cooling (IWC)

Full flow and side stream filters are two of the most common filtration systems used in cooling towers. In a full flow system, the filter must be sized in order to handle the system’s design recirculation rate and then installed during cooling tower installation, on the discharge side of the pump. A full flow filter continuously cleans all of the recirculating water. Side stream sand filters are a cheaper alternative to full flow and work by directing water through a bed of graded filter media, usually made up of compounds such as silica, anthracite or garnet. Side stream filters are often the preferred choice for many cooling systems due to the fact that they can be installed on an operational cooling tower and they can be cleaned while the cooling system remains online, avoiding the need for downtime.

A side stream filtration system composed of a rapid sand filter or high-efficiency cartridge filter is particularly useful for cooling systems that are subject to dusty atmospheric conditions. These systems draw water from the cooling tower’s sump tank, filter out sediments, and return the clean water to the tower. This enables the system to operate more efficiently with less water and chemicals.

With the increasing problems of pollution and water shortages, cooling tower operators must maximise cycles of concentration, which means more water reuse and, therefore, less make-up and chemical treatment requirements. Implementing appropriate filtration systems increases efficiency, reduces downtime, and helps control biological activity. Furthermore, it considerably reduces labour costs incurred from frequently draining and cleaning the cooling tower sediments.

We provide a variety of filtration and screening equipment using the SATI filtration systems range, which covers the entire field of normal filtration requirements from 5000µ down to 1µ, concludes Rusch.