Water is life, treat it right. IWC water filtration systems improve water quality.

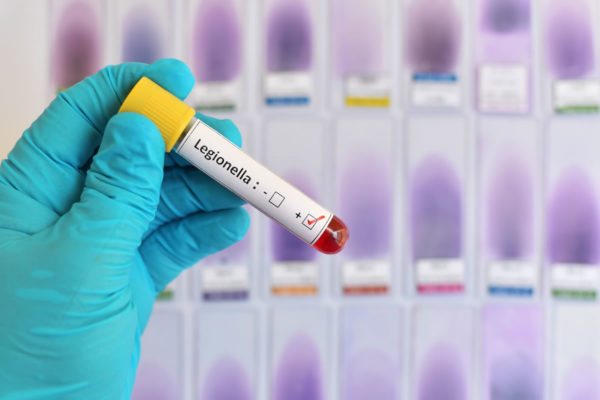

Cooling Towers are an integral part of any cooling system and need to be maintained to maximise efficiency and performance. If not done, the dirty process water will corrode the equipment, reduce heat exchange efficiency and drive up energy costs, leading to unnecessary water wastage. In addition, it can also lead to Legionella bacteria growth.

By installing an IWC water filtration system, the cooling water is maintained and water treatment issues like fouling and microbiological activity are minimised. This cost-effective method of addressing water treatment issues is done by filtering suspended solids from the cooling water.

Side stream filters are recommend for use in evaporative cooling water systems and work by directing water through a bed of graded filter media, usually made up of compounds such as silica, anthracite, or garnet. Side stream filters are the preferred choice for many cooling systems since they can be installed on an operational cooling tower and can be cleaned while the cooling system remains online, avoiding the need for downtime.

Filtration of cooling water means using a conventional type of filter which contains filter media, normally graded sand, or “mixed media” where the sand has an additional layer of graded anthracite on top of it. Anthracite/sand filter beds normally provide all the advantages of single-media filtration but require less backwash water than sand alone.

The major advantages of dual-media filtration are higher flow rates and longer filter runs. Filters of this design can remove suspended solids down to 20micron in size.

Cyclone Filters

IWC offers a range of skid mounted cyclone filter systems, ideally suited to smaller plants and comprise of the following skid mounted equipment.

- Feed pump

- Cyclone type separator

- Basket Filter

- Digital control system

Advantages include reduced water consumption and smaller footprint. Filters of this design can remove suspended solids down to 70 microns in size.

Our chemical dosing systems can either be stand alone or integrated into the process plants digital control system. Installation of equipment is a once off cost, however water maintenance costs are ongoing. Systems are tailored to suit any plant specific requirements.

IWC offers standardised automated dosing systems that include the following.

- Scale and corrosion control – dosing

- Biocide dosing

- Conductivity based bleed off sytems

- pH Control

Come clean, and chat to us about a water filtration system for your cooling system.