Willowton Group – Isando Plant

Isando, Gauteng, South Africa

Long-term partnership supporting edible oil processing excellence

As Willowton Group expanded its Isando Foods refinery to meet growing demand, the need for a reliable and scalable cooling solution became critical. Supporting key stages of edible oil processing, the new installation required a system that could deliver consistent performance while allowing for future growth. In partnership with IWC Industrial, Willowton implemented a tailored cooling tower solution designed to optimise efficiency, airflow, and long term operational stability.

Requirement

Willowton Group’s Isando Foods plant forms part of one of Africa’s largest independent edible oil processing operations, supplying essential FMCG products to the South African market. Having been in operation since 1970, the site has expanded significantly over the decades to support a growing product range that includes cooking oil, margarine, soap, and rice.

As Willowton developed a new refinery plant at the Isando facility, they required a reliable and scalable cooling solution to support critical refining processes. These processes, including degumming, neutralisation, bleaching, and deodorisation, all demand consistent and effective cooling to maintain product quality, process efficiency, and operational stability.

The challenge was twofold:

- To supply cooling infrastructure that could support initial capacity requirements, while allowing for future expansion

- To ensure the overall cooling tower configuration delivered optimal airflow and performance within the physical constraints of the site

Solution

IWC Industrial has been a trusted supplier to the Willowton Isando plant for many years, with the relationship dating back to 1998. Over this time, IWC Industrial has supplied multiple EWK, EWB, and FM cooling towers, along with ongoing spares and servicing support.

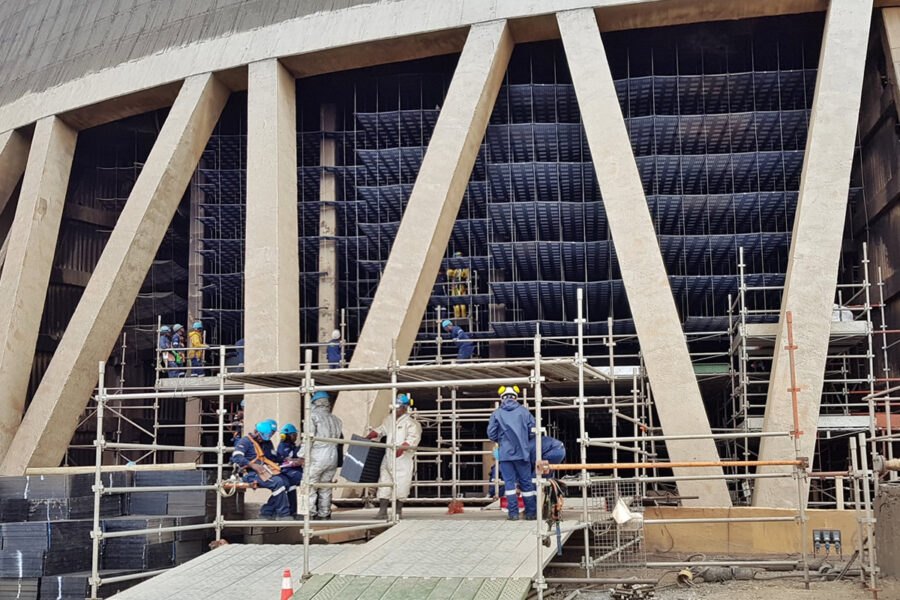

For the new refinery plant, we initially supplied two FM 205 cooling towers, designed to meet the plant’s original cooling requirements. As the refinery capacity increased, we responded by supplying a third FM 205 unit, ensuring the cooling system could keep pace with production growth.

Beyond equipment supply, IWC Industrial took on an advisory role, working closely with the Willowton team to optimise the overall installation.

This included:

- Advising on the best configuration for installing the towers over a common steel basin

- Identifying airflow improvements to enhance system efficiency

- Designing, manufacturing, supplying, and installing custom air inlet louvres, tailored specifically to the site layout and operating conditions

This collaborative approach ensured that the cooling solution was not only fit for purpose,

but optimised for long-term performance.

The Impact

The final cooling tower installation now plays a critical role in supporting multiple stages of the edible oil refining process, delivering consistent cooling across varying operational demands.

Key outcomes include:

- A scalable cooling solution that evolved alongside plant capacity growth

- Improved airflow and thermal performance through the addition of custom-designed air inlet louvres that prevent splash out which helps to save water.

- Enhanced process reliability across critical refinery stages

- Reinforcement of a long-standing partnership built on trust, technical expertise, and proactive support

By combining proven cooling tower technology with hands-on engineering advice and site-specific customisation, IWC Industrial helped Willowton Group ensure their Isando refinery expansion was supported by a robust, efficient, and future-ready cooling system.