A greener path for Dairy Farms: cutting energy consumption with IWC’s locally produced heat exchanger

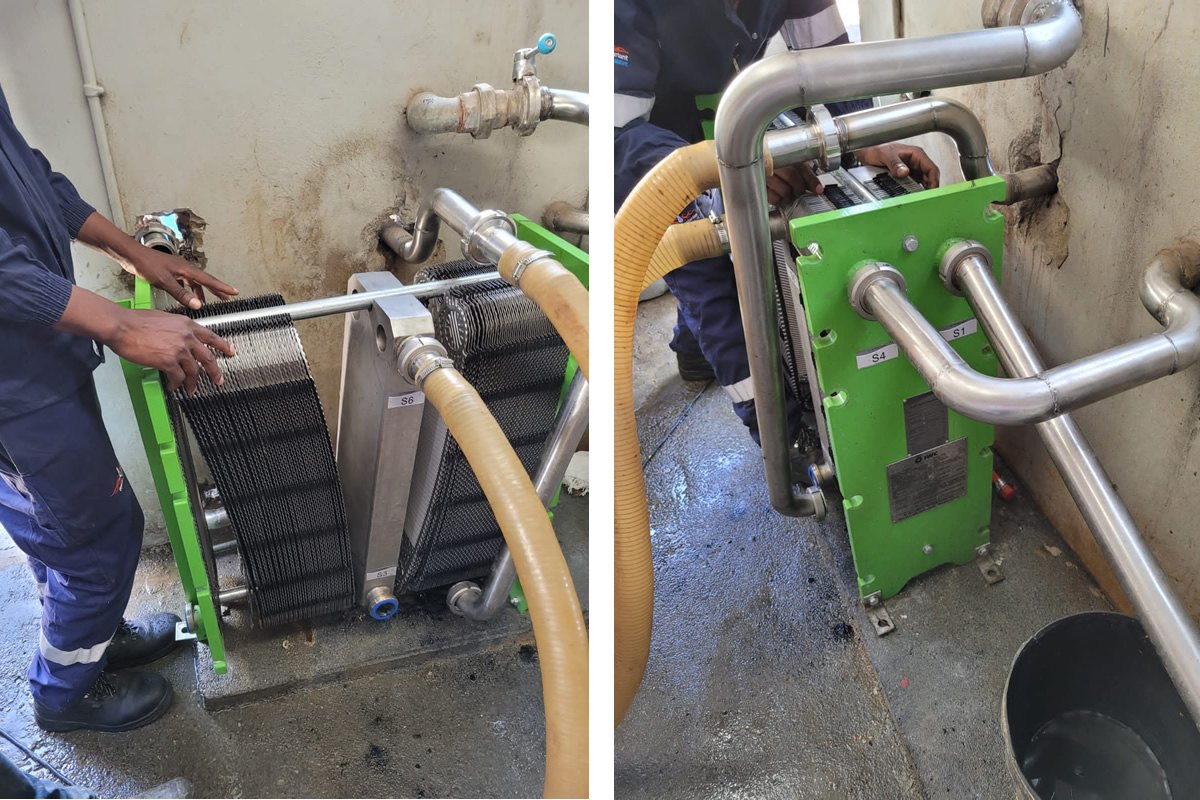

IWC were recently contacted by a local Dairy Farm to assess their current plate heat exchanger and provide guidance on a thermal solution that would cater to their increased milk cooling capacity needs of 8000 L/hr.

Their current plate heat exchanger was leaking, and the efficiency of the milk cooling process and milk production output was being affected. Milk cooling accounts for about 60% of the total energy costs of a dairy farm so it was imperative that the plate heat exchanger be repaired or replaced.

Our recommendation was to replace the current plate heat exchanger with a new IWC60B plate and frame heat exchanger. Our PHE comes complete with a locally manufactured mild steel painted frame, dairy unions and food grade SS316 plates and EPDM gaskets.

Further to the increased cooling capacity need, the new heat exchanger would also be required to cool milk in two stages. The first section will cool the milk from 37 °C to 25 °C using cooling water coming in at 22 °C. The second section would cool the milk further down from 25 °C to 6 °C using chilled water at 2 °C.

Milk cooling is a major contributing factor to the quality of milk on farms and the level of bacteria build up in milk. Cooling the milk immediately after milking will limit microbial growth and reduce spoilage of milk. Every degree in temperature above 4 °C elevates bacteria counts and decreases the shelf life of finished products.

The goal is to cool milk to 4˚C within 30 minutes of the completion of milking. Pre cooling and refrigeration are the core processes of cooling milk on dairy farms.

Before:

After:

Why Install a Plate Heat Exchanger

A PHE unit if operated efficiently to its maximum potential can have significant cost savings. A reduction of up to 60% in milk cooling costs is achievable. Higher milk quality is also achievable with reduced levels of bacteria growth during storage. The PHE can be cleaned on regular intervals to ensure the compliance to strict health and safety regulations.