Cooling Tower Maintenance and Legionella Control

Microbes are abound in the natural environment and are normally present in low concentration levels in the built environment. These systems are not sterile and will always contain some microbes. Generally, health hazards, which can lead to infections such as Legionnaires’ disease or Pontiac fever, or allergic reactions such are as humidifier fever, are created only when these microbes multiply to high concentrations.

The three main categories of microbes that can be found in the built environment are viruses, fungi and bacteria. However, only fungi and bacteria are prevalent in building/plant services and can colonize if moisture and organic nutrients are present. Fungi (e.g. mould) attach to hard surfaces and are readily able to grow in conditions of high humidity as they extract their moisture from the air. Bacteria can be controlled by the normal principles of hygiene, while fungi are difficult to eliminate and will germinate only when moisture returns.

Examples of systems that are only intermittently moist, but which are able to support fungal growths, are cooling coils, condensate trays, drain lines, ducting near cooling coils and humidifier surfaces.

Bacteria also prefer wet surfaces for growth but are generally to be found where the surfaces are submerged or at the interface between wet and dry areas. Colonization and growth of Legionella bacteria (the causative agent for Legionnaires’ disease), can take place in any water-based system if the water is warm and supplied with nutrients. Examples of such systems relevant to the built environment are cooling towers (and the like) used for heat rejection.

Other small industrial applications include dry cleaners, injection moulders, light industrial manufacturing companies including welding facilities, furnaces and steel manufactures, ice manufacturing, and breweries.

As Legionella bacteria are widespread in natural water sources, such as rivers, lakes, mud and soil, it is not surprising that they often present in cooling water systems. Absolute exclusion of these particular bacteria from water systems, may not be possible nor necessary and finding the bacteria does not by itself indicate that a source presents a risk.

Adverse conditions can be created by the build-up of sludge in storage vessels and possible dead legs in the piping systems. Regular cleaning, maintenance and disinfection of cooling systems and cooling towers, in particular is required.

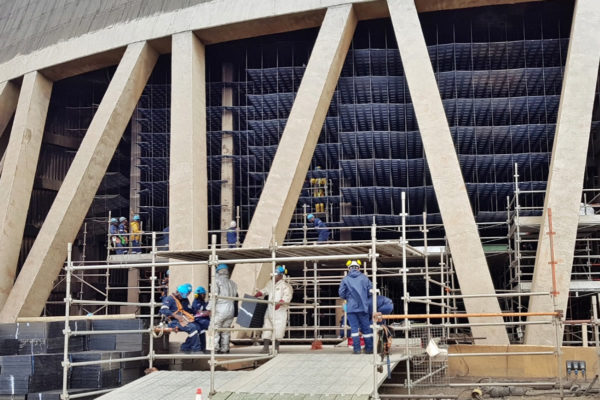

In the case of water cooling systems that make use of cooling towers to evaporatively cool recirculating water, the risk of disease can be minimized by the following these basic guidelines for Legionella control:

- Careful attention to system design and construction features.

- Use of drift eliminators.

- Siting of towers away from building air intakes and populated areas and discharges from kitchen exhaust systems.

- Maintaining the system in a clean and sound condition.

- Controlling water quality from when water is introduced into the system.

- Monitoring towers and water condition.

Is your cooling tower at risk for Legionella?

Why not contact us today for a free needs assessment of your plant. Our team of resident engineers specialise in water cooling maintenance and cleaning and provide unparalleled advice and service to both users and operators of cooling towers and industrial cooling systems.

Our team can ensure that your systems are clean, properly designed, commissioned, operated and well maintained, by deploying appropriate water treatment techniques.

Further explanatory information regarding the subject of microbial control of cooling water systems can be found :

- https://www.eha.sa.gov.au/public-health/cooling-towers-and-warm-water-systems

- http://legionella.org/about-the-disease/

- https://legionellacontrol.com/international/as-nzs-3666-part-3-legionella-control-australia/